A group of CIRCE researchers designs a reactor that reduces energy consumption in plastic recycling by 50%.

A group of researchers from the CIRCE Technology Center has developed an innovative reactor for the chemical recycling of plastics such as nylon and polyurethane, solving key points that allow the scaling up of this technology. This breakthrough allows the application of the process reducing energy consumption by at least 50% compared to methods that would require conventional heating technologies, marking a milestone in the field of circular economy by making it techno-economically feasible.

The project has been developed mainly within the framework of the European innovation project PolynSpire led by CIRCE, in which an interdisciplinary team from the technology center has worked on the development and optimization of the process, combining knowledge in industrial processes and computational simulation.

As a result, a robust solution has been designed that solves the safety limitations inherent to the process, integrating in a single operating volume both the chemical reaction vessel and the external resonant cavity, necessary for the efficient transmission of microwave energy. This approach not only simplifies system construction and integration into industrial environments, but also ensures safe conditions in high-pressure processes (up to 15 bar) and chemically corrosive media.

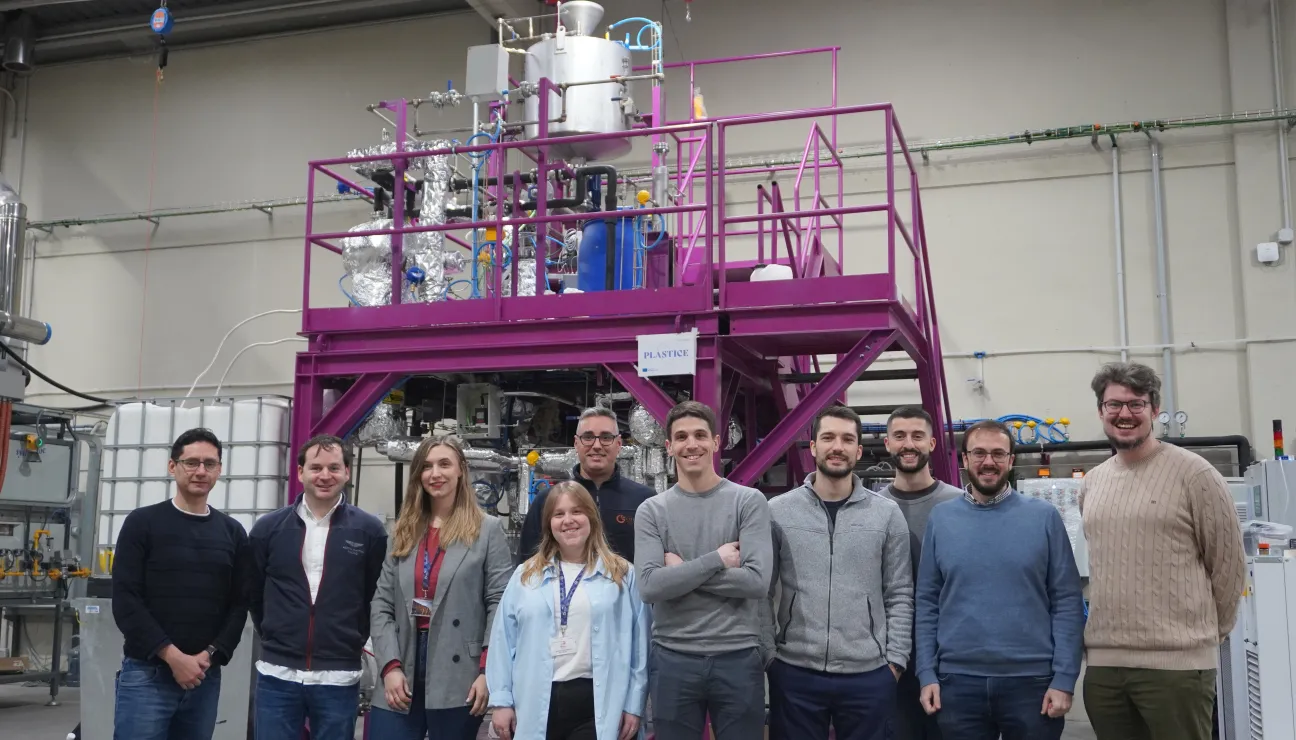

In parallel, the European Plastice project, also coordinated by CIRCE, has allowed progress in the application of advanced microwave heating technologies. These technologies combine antennas operating at different frequencies and powers to transmit radiation inside the reactor, achieving the temperatures required for the process (between 200 and 250 ºC) quickly and efficiently.

CIRCE develops innovative pyrolysis pilot plant design for plastics recycling

Thanks to Plastice, CIRCE has developed an innovative microwave-assisted pyrolysis pilot plant design, with a capacity to process up to 20 kg/h of plastic. This pilot plant, installed in CIRCE's industrial laboratory, will begin its experimental campaign in the first quarter of 2025, with the objective of chemically recycling LDPE fractions, producing oils that will later be cracked to obtain circular olefins. To guarantee the protection of this technology, CIRCE has registered the resulting service under Law 1/2019 on business secrets, ensuring its full legal protection.

With these advances, CIRCE reinforces its commitment to applied research and the development of sustainable solutions, demonstrating how the combination of computational simulation tools and advanced technologies can provide innovative answers to the challenges of waste management and industrial sustainability.