Boosting chemical recycling in the EU: new regulations and innovative technologies

Chemical recycling is gaining significant momentum as a crucial pillar in moving towards a more robust circular economy. The market for this type of reuse is expanding, especially in Europe, where nearly 50 new plants are expected to start operating in the coming years. This growth demonstrates the potential for innovative recycling solutions to be adaptable and economically viable on a large scale.

New legislation is currently under discussion in the EU that could establish a clearer and more favorable regulatory framework for chemical recycling, which could be a turning point. This regulation is designed to recognize and support the unique capabilities of this type of technology.

European regulatory decisions will be decisive for the future of chemical recycling. A key regulation under discussion is the calculation methodology for recycling performance, known as "Fuel Use Exempt". This regulation could allow products such as pyrolysis oil to be counted as recycled plastic, which would have significant implications for the industry, allowing greater flexibility in incorporating recycled materials into new products.

Although chemical recycling faces challenges such as tolerance to impurities and the need for a clear regulatory framework, its ability to process plastics that are not suitable for mechanical recycling positions it as a promising solution to increase recycling rates and reduce dependence on virgin resources.

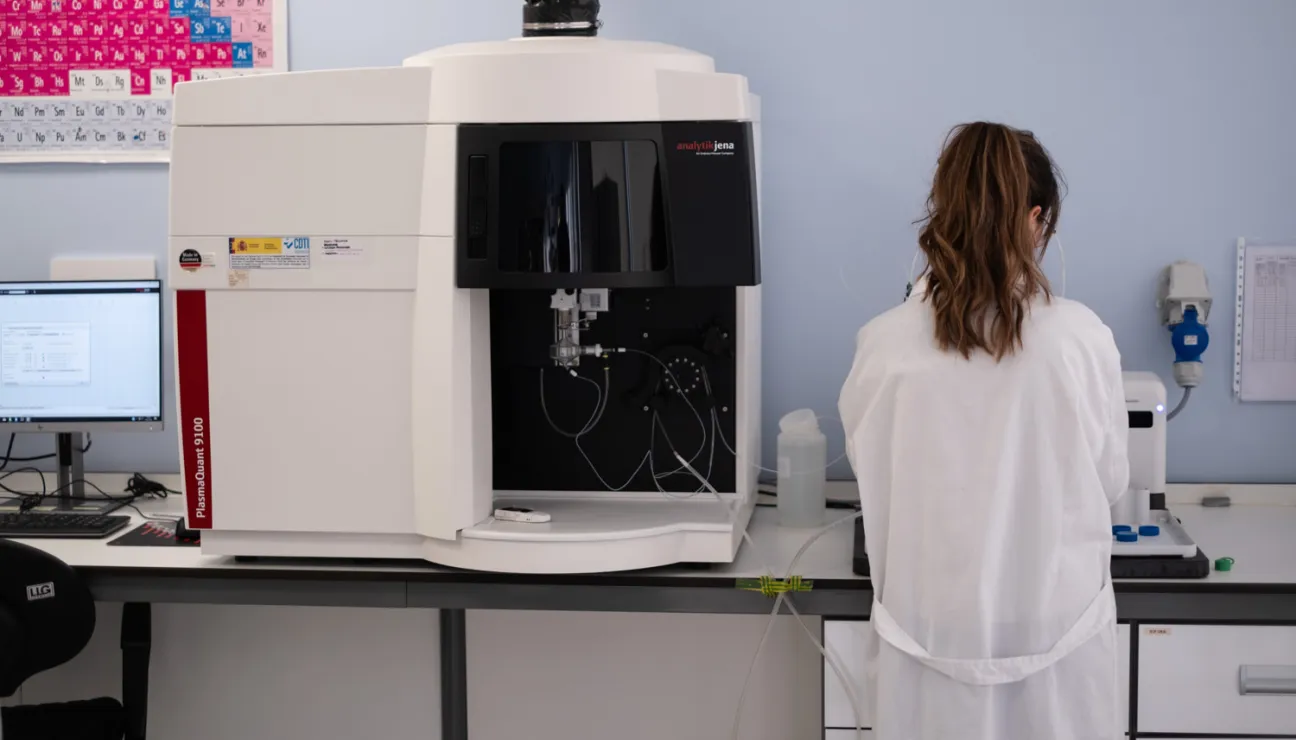

At CIRCE - Centro Tecnológico we have been exploring and supporting the development of chemical recycling technologies that complement traditional methods for years, ensuring that each innovation contributes to the same common goal. We apply processes such as solvolysis, pyrolysis or glycolysis -all of them assisted by microwaves- to valorize waste composed of complex materials such as wind turbine blades, solar panels or textiles, allowing their subsequent reuse.

The synergy between mechanical and chemical recycling

Mechanical recycling, known for its energy efficiency and cost-effectiveness, is excellent for processing clean and homogeneous plastic waste. However, it faces limitations when dealing with complex or highly contaminated plastics. In addition, there is a limit to the number of times a material can be mechanically recycled, as its properties degrade throughout the process. This is where chemical recycling comes into play, offering a powerful solution by being able to process a wider range of plastics and transform them into high-quality products, comparable to virgin materials.

This complementarity not only increases recycling rates, but also maximizes the circularity of plastics. An essential step in reducing our dependence on virgin fossil resources and mitigating plastic pollution.

Collaborative approach

At CIRCE, we not only actively participate in the development of advanced recycling technologies, but we also promote collaboration between different actors in the recycling value chain. This collaborative approach is crucial to overcome market and technological challenges, ensuring that waste is treated in the most appropriate way according to its characteristics and the desired final product quality, especially at a time when regulation is evolving. Thanks to this collaboration, the Aragonese technology center is participating in some highly relevant European projects such as Plastice, Redol, Cubic, Digintrace and Refresh.

Latest news