CIRCE accompanies GEDEME in its project for the national manufacture of lithium batteries in Cuba

The CIRCE Technological Center has become the key technological partner of the Industrial Enterprise for Informatics, Communications and Electronics (GEDEME) of Cuba in an innovative project for the domestic manufacture of lithium batteries. This project, financed by FIIAPP, aims to meet the domestic demand for batteries for the electric mobility sector in Cuba, especially to meet the demand for batteries for electric motorcycles that currently come from China.

In an effort to strengthen the local industry and ensure efficient and competitive production, CIRCE has provided specialized training to the GEDEME team, focusing on the entire value chain of lithium battery manufacturing, from production to end of life. This technical training guarantees the quality and safety of the production process. In addition, it allows adapting the capabilities of the company and its employees to the production process and facilitates the start-up of the plant with a more customized work plan.

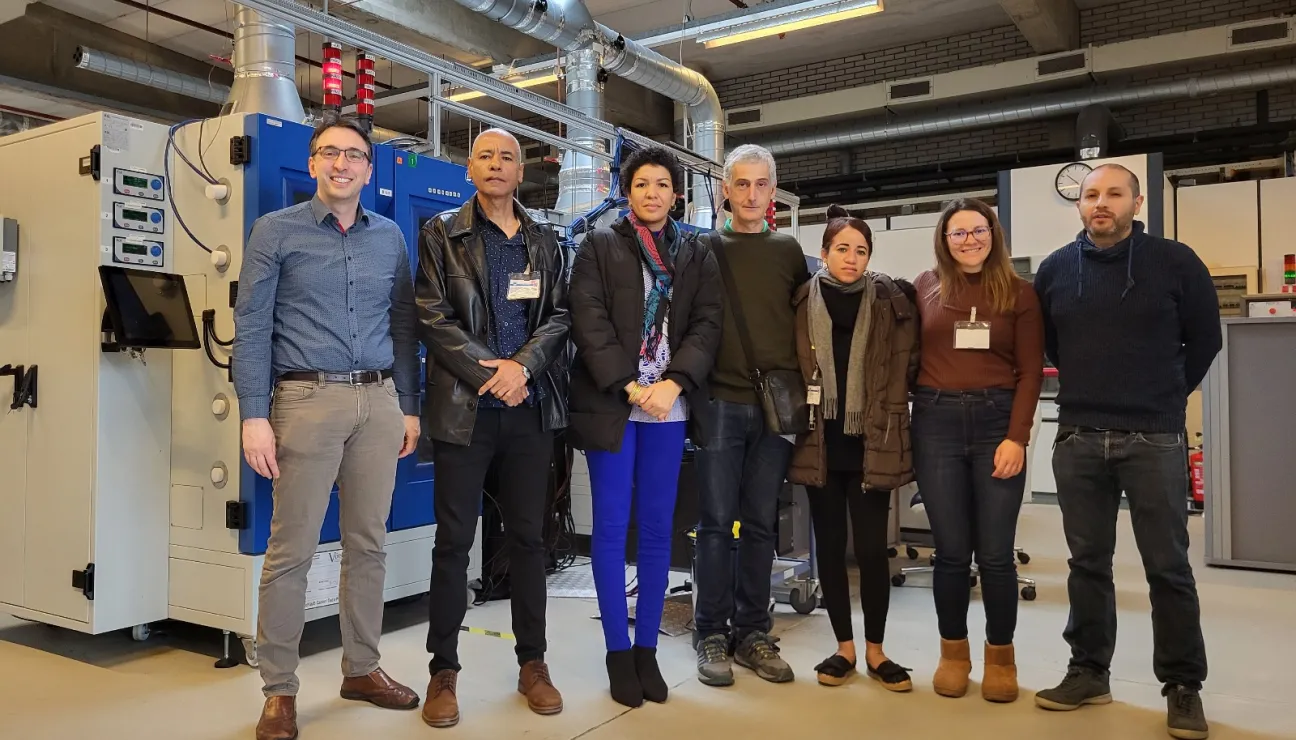

In addition, CIRCE accompanied GEDEME delegates to different European companies and technology centers (CIDETEC, EcarACCU, JRC-Petten) that develop activities related to the manufacturing and end-of-life stage of batteries. This activity allowed the delegates to broaden their knowledge of advanced technologies, best practices in battery manufacturing, quality processes and sustainability.

The technology center has also helped design a production model adapted to the needs of the Cuban context and access to raw materials, with a strategy that evaluates the existing industrial capacity and defines a business plan aimed at maximizing the viability and efficiency of the project. This approach seeks to boost the local manufacture of lithium batteries and consolidate a key sector for the country's energy transition.

With an initial production capacity of 40,000 batteries per year, the implementation of LiFePO4 (LFP) technology represents a crucial step towards safer and more durable electric mobility. Furthermore, the integration of maintenance and recycling services within the production model will guarantee the sustainability of the project, prolonging the useful life of the batteries and reducing dependence on new raw materials.

This advance positions Cuba on the road to greater technological autonomy in the energy sector, promoting the development of innovative and sustainable solutions for electric mobility.

CIRCE accompanies the sector in its technological challenges

The growth of the electric vehicle market has boosted demand for lithium-ion batteries, with forecasts of reaching a global production capacity of 6 TWh by 2030. However, this progress faces key challenges:

- Shortages of critical materials: battery production requires, among others, lithium, graphite, cobalt and nickel, minerals whose extraction and refining are mostly controlled by China. It is estimated that demand for lithium will triple by 2025, prompting the search for alternatives such as sodium or the recycling of used batteries.

- Safety: Although batteries have improved in stability, they still present thermal runaway risks, with incidents reported in different applications, which has prompted the development of measures to mitigate the risk of fires and the creation of standards.

- Durability and degradation: An average electric vehicle loses between 10-20% of capacity after 1,000 charge cycles, which limits its useful life and raises the ToC (Total Cost of Ownership). Cathode and anode optimization aims to reduce this degradation.

- Environmental impact: Only 5% of lithium batteries are properly recycled. Europe and the USA have begun to regulate their collection and reuse, promoting the circular economy and reducing dependence on new extractions.

To ensure the sustainability of the sector, the industry is committed to new chemistries, improvements in recycling and a more efficient management of materials, ensuring that electric mobility is a viable long-term solution.

To contribute to this, CIRCE works on the development of technological solutions that facilitate the recovery of batteries at the end of their useful life (2nd life) and industrial waste and the optimization of recycling processes, contributing to a more sustainable and resilient industry. From the improvement in the separation and use of materials to the evaluation of new storage technologies, driving the transition towards a more circular model, favoring the recovery of key materials and closing the life cycle of these essential devices for electric mobility.

.jpg)