Microwave-assisted pyrolysis technology to efficiently enhance the circularity of plastic and textile waste

Despite ongoing efforts to reduce plastic waste, currently only 20% of the total production is recycled. This is partly due to obstacles such as the presence of complex fractions in waste streams, multi-layer materials, or mixtures of plastics with other types of waste that cannot be easily sorted. At the end of their life cycle, these fractions of plastic waste end up in landfills, are incinerated, or may even accumulate on beaches, in forests, rivers, and oceans, causing significant environmental impact. To increase the valorization percentage of this type of waste, new solutions need to be developed to complement traditional mechanical recycling. This is where the PLASTICE project comes in, coordinated from Spain by the CIRCE technology center, with a total budget of nearly 20 million euros, approximately 15 million of which is funded by the European Commission.

The project, which has just started its activities in June 2022, will address the development and demonstration of new valorization processes for various plastic and textile wastes over the next four years, with the aim of obtaining base chemicals for polymer synthesis, thereby enhancing the circularity of these materials. This will be made possible through the design, development, and demonstration of thermochemical technologies such as microwave-assisted pyrolysis, hydrothermal liquefaction, gasification, or biological technologies like enzymatic hydrolysis.

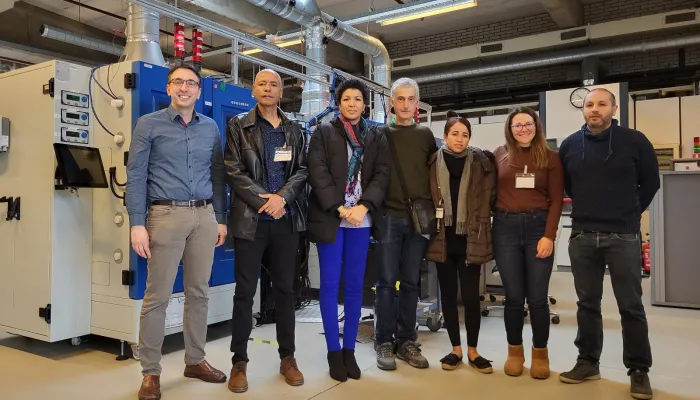

PLASTICE will address these processes from laboratory scales to the scaling and validation of these technologies to TRL 6-7 levels in collaboration with various waste managers and industries in the European Union, such as Urbaser, Cogersa, Agovino PRT, and DKW. The liquid products obtained will be subsequently validated by companies in the petrochemical and textile sectors such as Total Energies and Korteks. Overall, PLASTICE aims to reduce the carbon footprint of current chemical plastic recycling processes by around 60% compared to existing recycling routes.

PLASTICE will address these processes from laboratory scales to the scaling and validation of these technologies to TRL 6-7 levels in collaboration with various waste managers and industries in the European Union, such as Urbaser, Cogersa, Agovino PRT, and DKW. The liquid products obtained will be subsequently validated by companies in the petrochemical and textile sectors such as Total Energies and Korteks. Overall, PLASTICE aims to reduce the carbon footprint of current chemical plastic recycling processes by around 60% compared to existing recycling routes.

In addition to coordinating the entire project, CIRCE will contribute its expertise in microwave technology, renewable energy integration, resource optimization, and circular economy. Furthermore, CIRCE will lead the application of machine learning and artificial intelligence techniques, as well as life cycle analysis (LCA), to make these technologies profitable and efficient in recycling plants.