PHIL and HIL Laboratories: The Key Link in Electrical System Validation

In the traditional centralized power generation model, most power comes from large power plants, whose high inertia enables unified control of energy balance and system stability. However, the expansion of decentralized renewable sources with their associated electronics and the incorporation of new loads, such as electric vehicles, have significantly transformed the energy landscape, especially in the distribution network.

The Major Challenge of Compatibility in Electrical Networks

The ability of different systems, devices, or components to communicate and operate efficiently within the same network is essential in the electrical sector. This means that equipment from different manufacturers must work together seamlessly, ensuring a stable and secure power supply. Ensuring this integration is key to improving efficiency, minimizing failures, and facilitating the adoption of new technologies in the electrical infrastructure.

Some of the main challenges of modern networks include:

- Diversity of manufacturers: Equipment from different brands may not communicate efficiently.

- Communication protocols: Incompatibilities in systems that create difficulties in interoperability.

- Constant technological evolution: The introduction of new technologies that require continuous validation.

Focusing on a concrete example, the electric vehicle sector has established standards such as the CCS (Combined Charging System), which even requires extensive testing, such as well-known testivals, to ensure interoperability. If such tests are necessary in this advanced sector, it makes sense to apply them in other environments as well.

To prevent failures and ensure safe operation, it is essential to validate and verify these interactions in controlled environments. But how can this be done efficiently? To help you secure your equipment, we offer validation testing at CIRCE’s in-house laboratories.

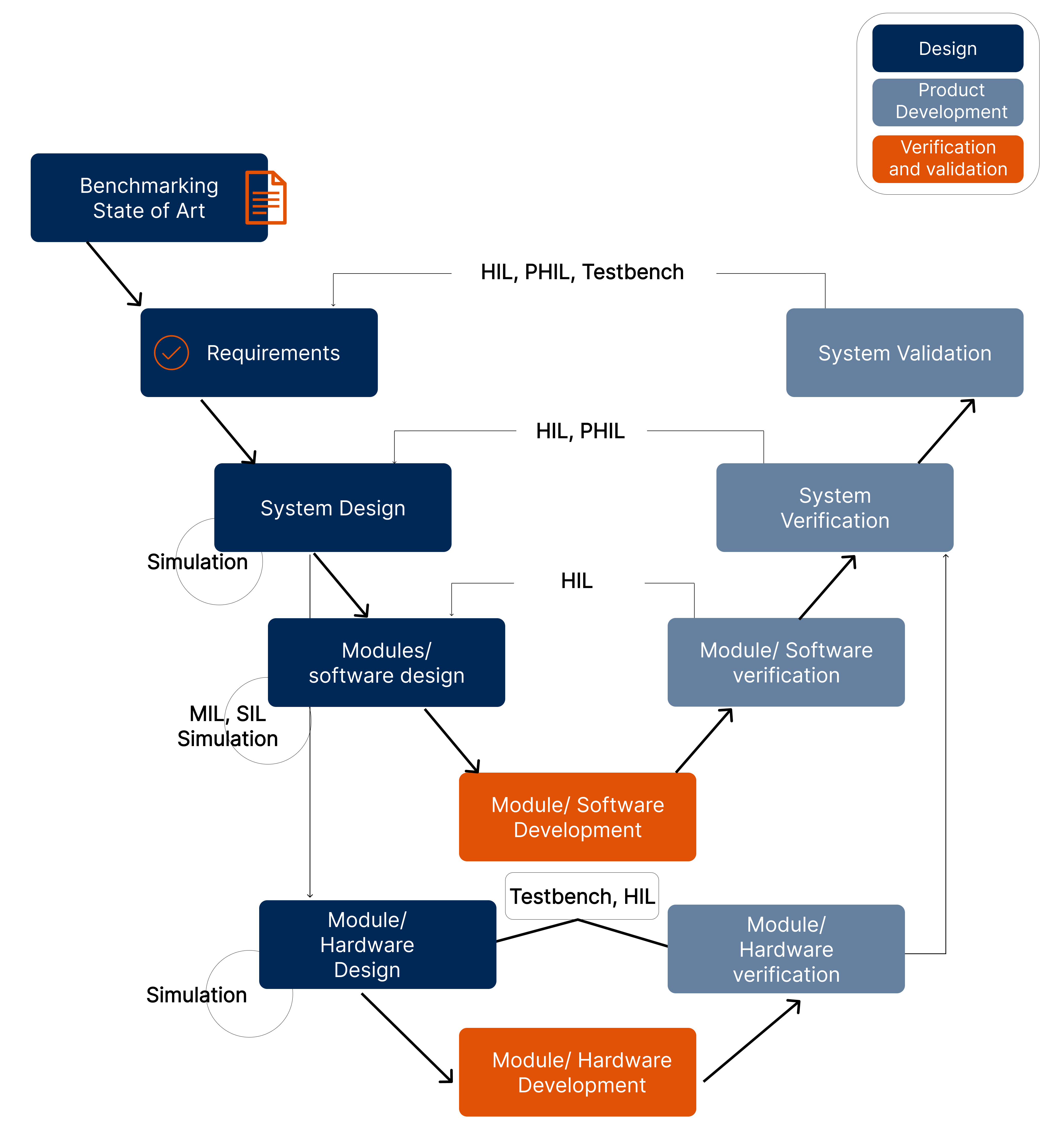

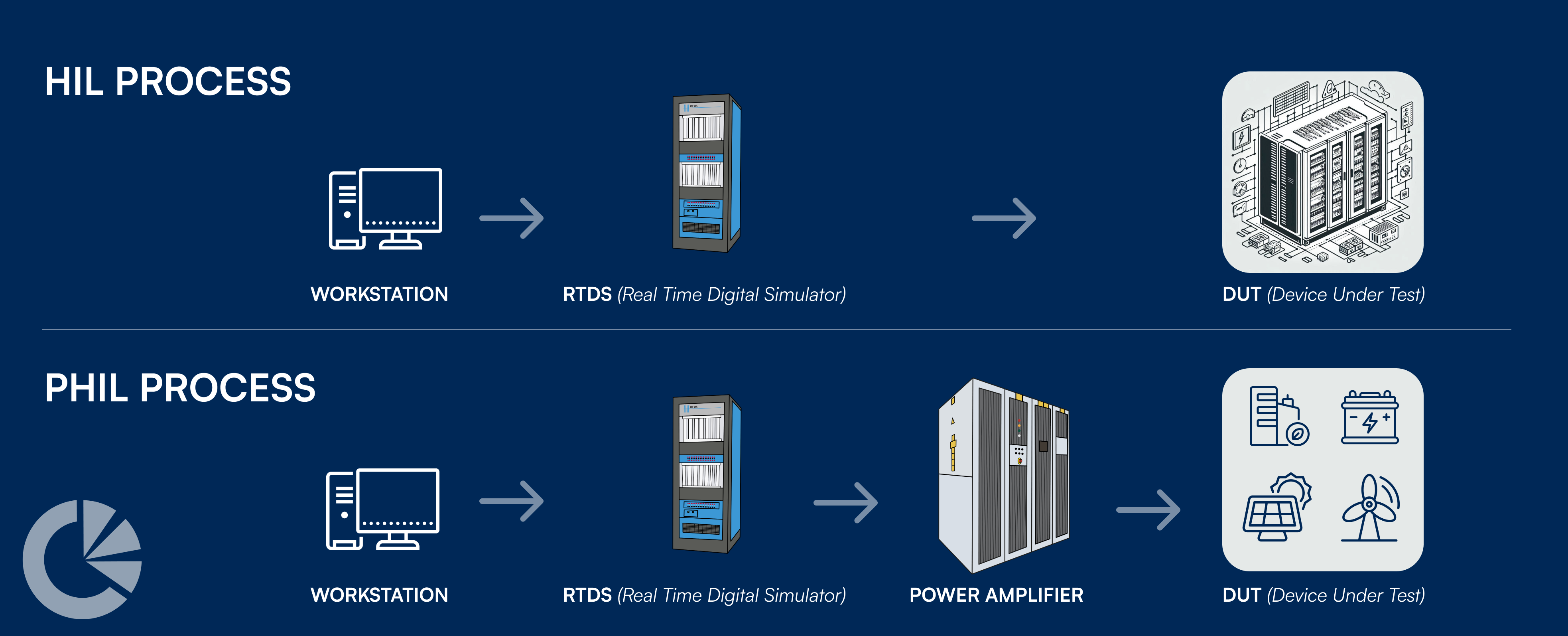

What is the Difference Between HIL and PHIL Methodologies? Discover the Key Role of RTDS

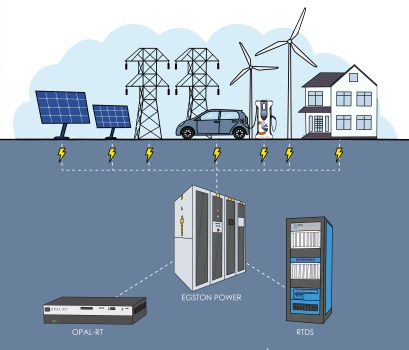

We work to help grid operators minimize risks and ensure a safe and efficient transition to a renewable energy-based system. To achieve this, we implement advanced validation methodologies that ensure the reliability, stability, and compatibility of grid-connected equipment, such as:

HIL (Hardware-in-the-Loop)

This method allows simulating the real environment without the need for physical testing.

- Ideal for energy management systems and smart controllers.

- Reduces costs and accelerates the development of new devices.

- Example: We can reduce failures by up to 30% in real-world deployments by validating battery controllers in smart microgrids before their rollout.

PHIL (Power Hardware-in-the-Loop)

Takes it a step further by enabling the testing of equipment interacting with real power signals.

- Used for the validation of inverters, converters, and energy storage systems.

- Simulates real conditions with high precision.

- Example: A 20% improvement in the energy efficiency of inverters through software adjustments based on PHIL testing.

RTDS: A Key Tool in Equipment Validation

Although we previously detailed its features in the article "5 Challenges Solved by the RTDS Real-Time Simulator," RTDS provides a controlled environment where interactions between multiple devices within a simulated electrical network can be evaluated.

- It helps detect communication and compatibility issues early through system integration testing for energy management networks under different operating scenarios.

- It can reduce interoperability issues detected after field installation by up to 25%.

How Can CIRCE Help You?

Ensuring supply stability and equipment compatibility is crucial to preventing failures, improving efficiency, and complying with regulations. At CIRCE, we support you in this process with validation solutions that allow you to anticipate problems, minimize risks, and optimize the performance of your assets before implementation.

Our services are designed to help you:

✅ Prevent failures and improve stability

- Simulating grid events (frequency variations, phase shifts, harmonics) to assess equipment response under different scenarios.

✅ Ensure regulatory compliance

- Pre-certification of grid codes to ensure equipment meets current regulations and facilitate grid integration.

✅ Validate the integration of new technologies

- Testing photovoltaic systems and energy storage solutions (batteries, hydrogen, electric vehicles) to ensure their compatibility and efficiency.

✅ Protect electrical infrastructure

- Validation of protection equipment in AC and DC systems, ensuring proper operation under critical conditions.

✅ Adapt to global markets

- Compatibility testing for American (60 Hz) and aerospace (400 Hz) networks, facilitating the internationalization of your equipment.

✅ Optimize performance and thermal efficiency

- Electrical and thermal analysis of power magnetic components to improve durability and operational efficiency.

With CIRCE, you not only validate your equipment but also reduce uncertainty, minimize field testing time, and optimize your network to tackle future challenges.

Need more information? Contact us!