Machine vision: GPT Chat in imaging for industry

Can you imagine a technology capable of obtaining, processing and interpreting images intelligently? Something like Chat GPT but applied to the visual area. In this way, the industry will be able to analyze and decode the information obtained during production processes to make the best decisions and act in the most convenient way through an automated process.

But what does Chat GPT say about the most promising applications of machine vision in industry?

Here it goes:

And is it profitable for the industry?

To understand it, machine vision solutions are tools that, like Chat GPT, are based on artificial intelligence and are able to observe, process the captured information and act intelligently in an automated way. But how to understand the value that the technology can offer to the industry? One of the most promising applications is that of quality control of any product, especially those involving production processes whose modifications entail high economic costs. In this sense, machine vision applications can be used for such everyday problems as ensuring the homogeneity of products - whether a bottle has the same amount of liquid, whether a part is positioned in the same way as the rest on the conveyor belt -, for detecting small flaws or even for product revisions involving changes in color.

Color matching, a solution for detecting unnoticeable changes

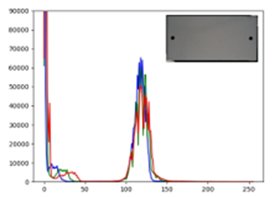

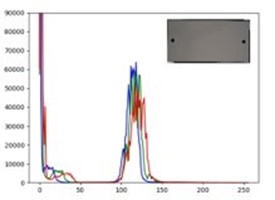

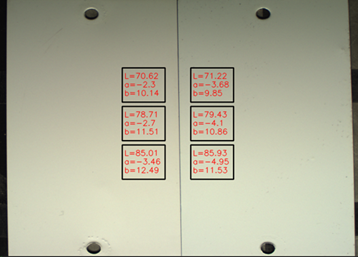

In the latter case, color matching is useful, a solution that allows to detect imperceptible changes in the color of a product. It may help you to know the value that this tool can offer to the industry knowing one of the real cases that we have executed from CIRCE in the automotive sector. One of the most relevant challenges of the automotive industry is to detect faults in the bodywork that are imperceptible to the human eye but that represent a quality defect in the final product and that forces to repeat the manufacturing or painting process of the part with all the cost that this entails. Do you notice the difference between these two pieces of sheet metal?

You probably cannot perceive that each of the sheets has a different shade. However, the solution based on artificial vision developed by CIRCE makes a clear diagnosis:

The process developed so far has consisted of detecting differences in shades through cameras and models that, once deployed in the production plant, do not affect the production process and help plant managers to detect and correct these faults and offer a high quality standard of your product to your customer.

Do you need to ensure that your quality controls are correct and do you think this type of solution can help your industry? Tell us about your challenge