CIRCE, leader in the development of lithium battery recycling technology

Can you imagine 78 soccer fields filled with 350 tons of used lithium batteries? That's the challenge facing the electric vehicle industry. While these technologies promise to reduce CO2 emissions, they also bring a dilemma: the accumulation of discarded batteries. What should be done with them? The end of their life not only poses an environmental problem but also presents a logistical and technical challenge for recycling.

The European Union is taking proactive steps with regulations mandating the integration of recycled materials into new batteries. By 2031, 16% of cobalt, 6% of lithium, and 6% of nickel used in new batteries must come from recycled sources, directly impacting producers and recyclers.

CIRCE – Technological Center, specializing in providing innovative solutions for sustainable development, is anticipating the new regulations and is immersed in developing recycling technologies for the electric vehicle industry. These solutions promise to mitigate environmental problems and aim to become an engine of economic development.

Direct recycling, the most efficient method

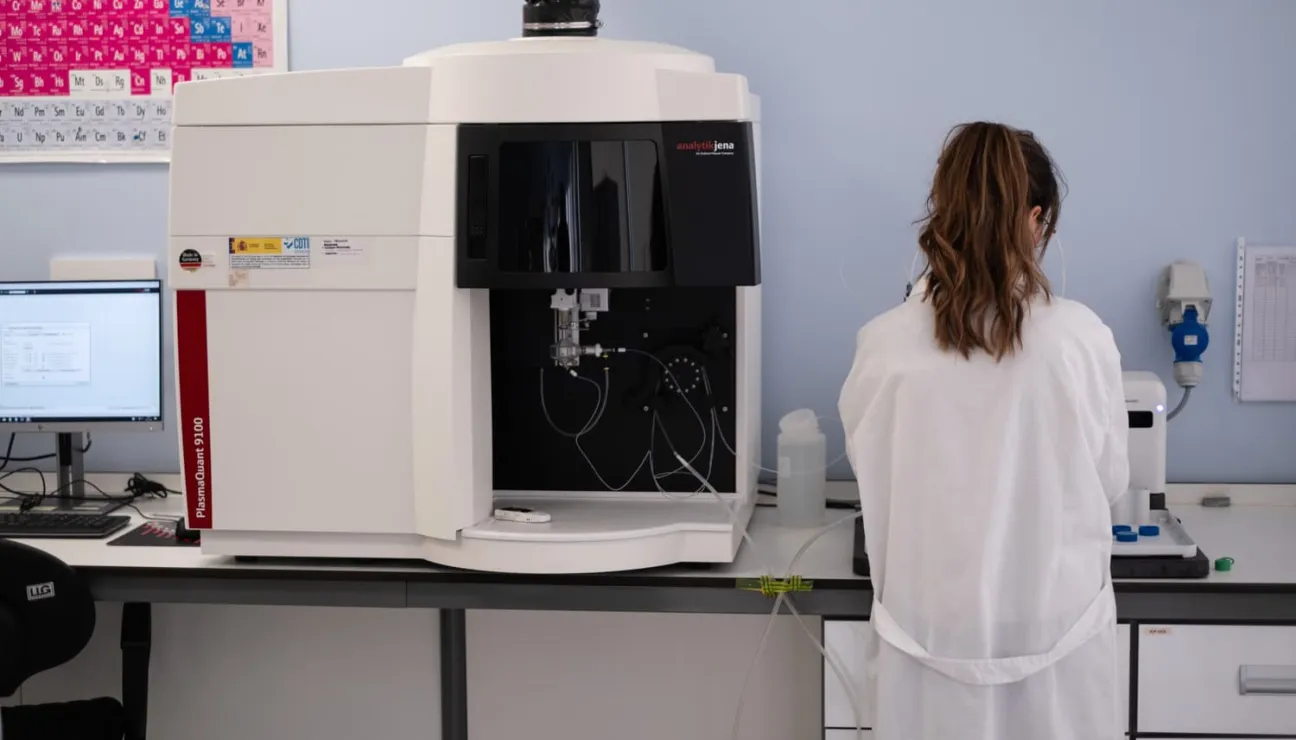

CIRCE offers a comprehensive recycling service that includes battery diagnosis, implementation of the most suitable recycling methods, and advanced technologies to maximize material recovery. These services cover the analysis of used battery condition and chemical composition, application of advanced technologies to maximize material recovery, and reintroduction of these materials into new battery production, promoting a closed and sustainable product lifecycle.

Their experts specialize in implementing processes that allow the recovery and reuse of valuable materials like cobalt, lithium, and manganese. However, direct recycling is proving to be the most efficient method because it enables the recovery of battery components without degradation, reintegrating them into production and offering both economic and environmental advantages.

Development of other recycling technologies and leadership in R&D

The technological center not only excels in battery recycling but also focuses on strategic waste recycling. An example is wind turbine blades, with an expected generation of 25,000 tons annually by 2025 and up to 52,000 tons/year by 2030, alongside a European regulation that prohibits landfill disposal of these wastes from 2025. In this case, CIRCE is researching microwave-assisted solvolysis for wind turbine blade. This technology involves degrading the blade using a solvent heated by microwaves, achieving shorter reaction times and higher efficiency.

The same technology is being applied in the REDOL project for textile recycling. Specifically, they are using microwave-assisted glycolysis to obtain polyester monomers and purify them for reintroduction into the production process.

Furthermore, CIRCE is also involved in recycling photovoltaic panels, PCBs, composites, and plastics. In all cases, they conduct techno-economic evaluations of processes to ensure that technologies transferred to the market are profitable. Similarly, they focus on reusing all reagents used to increase sustainability.

Learn more about the most innovative recycling and waste valorization technologies, focused on traditionally complex wastes such as construction debris. These include novel techniques like artificial intelligence with advanced computer vision and machine learning systems.

Latest news