A new system to recover and utilize heat from large-scale industrial processes

INDUS3ES is an R&D&I initiative funded by the European Commission that is developing an innovative system to recover and utilize waste heat from industrial processes, which is typically not used effectively. This allows industries to improve their efficiency, competitiveness, and sustainability.

The project has a budget of €3.86 million granted under the Horizon 2020 program, with the participation of 10 entities from various European countries.

From Spain, AIGUASOL, a detailed engineering firm, REPSOL and FERTINAGRO as demonstration partners, TECNALIA as the designer and project coordinator, and CIRCE, which will be responsible for the market analysis of the developed solution, as well as studies on process performance, analyzing improvements from a thermodynamic perspective, and industrial replication, are participating in this initiative.

Currently, energy-intensive industries generate large amounts of low-temperature waste heat that is largely discarded because it is low-quality energy. Additionally, recovering this energy using current technologies requires significant financial investment.

Improving Competitiveness, Advancing Towards Decarbonization, and Enhancing Industrial Efficiency by Up to 25%

INDUS3ES aims to overcome these barriers by providing a new solution that not only improves the competitiveness of these companies but also advances the decarbonization of European industry.

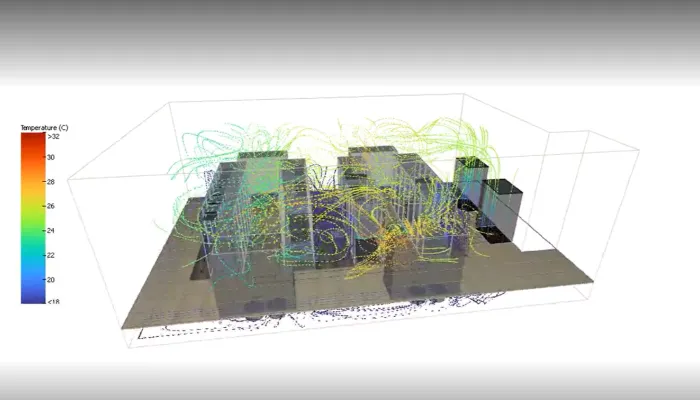

To achieve this, the project will develop a 'heat transformer', an absorption technology that recovers and revalues low-temperature waste energy (between 70 and 110ºC), with a portion of it being returned to the process at a higher temperature (between 120 and 150ºC).

This resulting energy flow can be utilized in other processes without any additional fuel costs, leading to a substantial improvement in energy efficiency, which could reach up to 25%.

Studies conducted by the project reveal that, thanks to this cost savings, industries that integrate the INDUS3ES solution will recover their investment within a period of 2 to 4 years, depending on the process, production capacity, and the fuels used. The project partners are placing special emphasis on achieving a market-ready solution that can be easily adapted to various processes and industrial sectors.

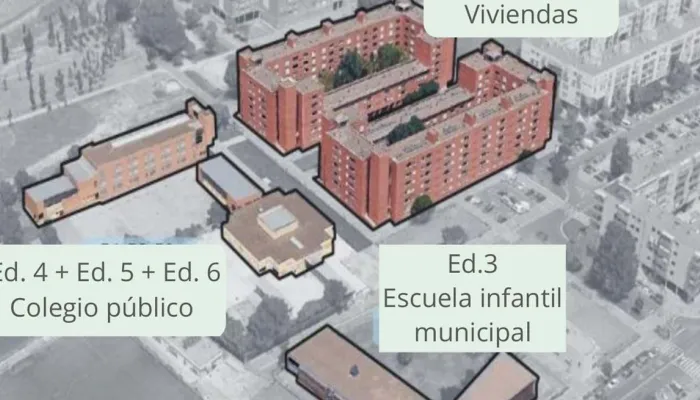

The system will be demonstrated in a petrochemical industry (TÜPRAS, Turkey), allowing for an analysis of integration details as well as business model and operational aspects. In parallel, the application and integration of the heat transformer in REPSOL and FERTINAGRO's industrial processes will be evaluated.

In addition to reducing energy consumption, the project will also study the environmental impact of this new prototype, as well as its production and maintenance costs, which opens the door to increasing the global competitiveness of European products.

On the social aspect, studies will also be conducted on market acceptance of the new technology and the potential impact on employment generated by the production of such solutions, as energy efficiency is expected to contribute to fostering a more sustainable economy in Europe.

For more information, visit the website: https://api-indus3esweb.azurewebsites.net/

Latest news