Electrical pulse technology for improved food preservation

The project will try to revolutionize the wine, oil, tomato, fruit juice and cider industries, hoping to expand to many other products. It will use an innovative technology in food processing to improve the properties and sustainability of the whole process: high voltage electrical pulses.

The benefits of "non-thermal" processing

High-voltage electrical pulses are a 'non-thermal' technology, which manages to generate effects on foods similar to those caused by heat, but at lower temperatures than heat treatments. As a result, they are more environmentally friendly than traditional technologies and eliminate the negative effect of heat on the sensory and nutritional properties of foods.

These technologies are very attractive for the food industry, as they can improve food quality and reduce energy costs and the environmental impact of the process.

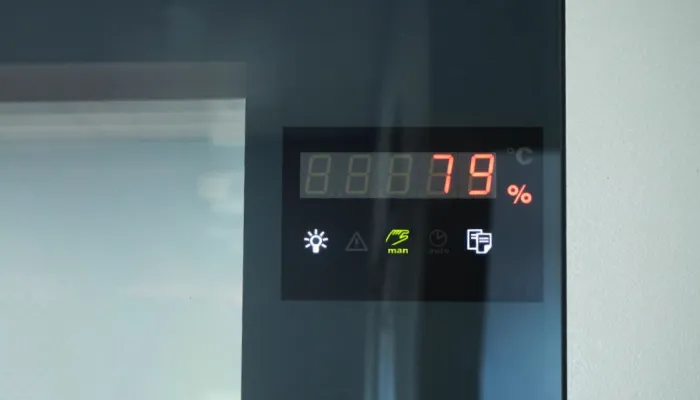

Processing with this new technology consists of the intermittent application of high voltage electric fields (0.5-30 kV/cm) with a duration of one millionth of a second to a food placed between two electrodes. This treatment causes a phenomenon called electroporation: pores are formed in the membranes of the microbial cells and the food.

Electroporation of the membranes of the microorganisms inactivates them at lower temperatures than those used in thermal processing, which prolongs the shelf life of the food. In addition, safe food is obtained without the heat affecting its sensory and nutritional properties.

Cost reduction thanks to electric pulses

Many operations in the food industry are based on the extraction of components located inside cells. For example, the phenolic compounds responsible for the color, sensory properties and health benefits of red wine must be extracted from inside the cells of the grape skin; oil, from those of the olive pulp.

The formation of pores in the cell membranes by means of a high-voltage electrical pulse treatment facilitates the extraction of these components, reducing energy costs. In the last five years or so, various foods processed by high-voltage electrical pulses have appeared on the market.

The main applications of this technology are the pasteurization of fruit juices and the treatment of potatoes for the manufacture of frozen potatoes for frying. However, the application of this technology in the food industry is still limited.

Within the framework of Fieldfood, industrial demonstrations of its viability will be carried out to improve food quality, optimize food processing, reduce energy costs and introduce new foods into the market.