Industrias Pardo launches Spain's first eco-designed hospital bed

Industrias PARDO has become the first company in the sector in Spain to be certified with the ISO 14006 standard for eco-design in the design, manufacture and marketing of hospital beds, a certificate that complements the environmental management system during the design and development processes of its products. Awarded by AENOR, the certificate validates the ecodesign strategy and criteria that will accompany the design and development process of all its models.

This has been possible thanks to the joint work of Industrias PARDO with the CIRCE technology center. During the last two years, both have worked on the development of the new procedures that allow the ecodesign of the products, using the "New Care V3 ACT" hospital bed model as a reference. In addition, in the process, the Environmental Product Declaration has been developed under the Environdec international scheme of this model, a pioneer in its sector, as there is no other hospital bed with this accreditation.

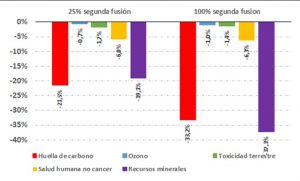

Objective: manufacture of a bed with 100% second-melting steel

The result is a new model that manages to reduce 240 kgCO2eq, 5% of the annual emissions of an average Spaniard, over the entire useful life of the bed. The ultimate goal is to manufacture 100% with second-melting steel to save 372 kgCO2eq, which would represent a 33.5% reduction compared to the initial model. With all this, the new eco-design process has managed to reduce the carbon footprint by 21.5% and mineral resources by 19.1% compared to the initial process.

This reduction has been possible thanks to the increased use of recycled raw materials in its manufacture, with 25% of the final product being made of second-melt steel. In addition, the manufacturing process has been supplied with electricity with a more decarbonized electricity mix, which has cut emissions by 30%, and more sustainable packaging has been used, with a 20% increase in recycled cardboard content.

Similarly, the bed has incorporated a new version of the user manual to introduce tips on how to use it, so that the useful life of the batteries can be extended by up to 2 years, and the materials and recyclability of the components at the end of their life have been marked, increasing the bed's recycling capacity to 90% for cardboard and metal components and 50% for plastic components.

The improvements made in the "New Care V3 ACT" model can be applied to Pardo's entire product portfolio, since the methodology used can be implemented in other business lines such as domestic beds or geriatric and hospital furniture, generating a multiplier effect in terms of environmental impact reduction.

PARDO Industries was already certified under the ISO 14.001 Environmental Management Systems, so the environmental impact was already considered in the day-to-day actions, but the implementation of eco-design is a step further, having to consider in each new product or in each modification of the design of a product the environmental impact throughout its life.

Latest news